This is the fourth of a series of questions from SO4IT a Swedish IT consultancy company who are using GigaSpaces technology to build a

SID based Order Management system for Communications Service Providers.

So4It: The Order Manager application will look something like this

- CustomerOrderDetail place(CustomerOrder customerOrder)

- CustomerOrderDetail cancel(final OrderId orderId)

- CustomerOrderDetail get(final OrderId orderId)

Inside the order manager I know have to decide how to

implement the flow of the order. I will

not use a complicated rule engine I will just have a simple mechanism for

it. But the question is how this

mechanism will work.

I guess that you create CustomerOrderItems that are context

aware. I mean we can have a

ProductOfferingCustomerOrderItem that will have the product offering with its

ProductSpecifications and the selected ProductSpecificationValues. Correct?

Andrew: The

CustomerOrderItem is linked to the ProductOffering through

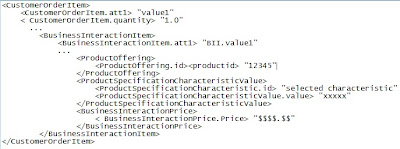

BusinesInteractionItem (see below)

So the XML (and I’m so hot at writing XML but I hope this

gives you an idea) will be something like

So the OrderItem just refers (indirectly) to the Id of the

ProductOffering, the Price (in BusinessInteractionPrice) and the quantity

ordered. The Order Manager will use the

ProductOffering.Id to find the ProductOffering and its related

ProductSpecification and ResourceSpecs and ServiceSpecs. If the customer has selected

ProductSpecificationValues then they would be in the XML as shown.

So4It: What do

you suggest I do to get the order manager to select the right "Provisioning

Conductor" for the CustomerOrder?

The alternatives, as I see it are:

- I could split the CustomerOrder into all the items and have a different "Provisioning Conductor" for each. If I do that I could have a simple registry for the "Provisioning Conductors" that checks the type of the CustomerOrderItem and returns the correct "Provisioning Conductor" based on that or maybe one or more values inside the CustomerOrderItem. OR

- I could choose a "Provisioning Conductor" based on the CustomerOrder, which will be the ProductOfferingCustomerOrder or something.

I guess it is a matter of granularity here and I could do

both but I was hoping you had some advice here, for example: how does the

functionality in a OrderManager look like usually, I guess it is a rule engine

or...? Just give me your views on this

if you have some. The most important

thing is how do you model the CustomerOrders and CustomerOrderItems in a real

system using the product offering.

Andrew: A Provisioning Conductor per Order Item is

the correct solution if you mean by “Provisioning Conductor” the actual service

that provisions the order. The Order

Manager must decompose the Order into individual items for provisioning –

probably equating to individual OrderItems, but a really sophisticated Order

Manager might group together similar order items before passing them off to other

services for Provisioning. The Order

Manager must also think about sequencing – there may be items on the order that

need to be provisioned first – for example sending out the handset (and waiting

for an acknowledgement of receipt) before getting a Provisioning Conductor to

provision phone number on the network.

A single order can have many different products on it – keep

the granularity at the order item level.

There is a form of rules engine that understands the Product structure

and the dependencies on the provisioning steps.

1 comment:

Hi, I would like to share some details regarding the decomposition process when the OM sends the CustomerOrder.

During 2007-2009 I've been working with a worldclass provider(the consultant Division)to design our "best practice" processes. So following you'll find additional features that decomposition process could handle:

- NRP (Not Return Point): To manage modification requests

- Delta analysis: to create SOs just for new ones.

- Defining if technical feasibility should be confirmed

Post a Comment